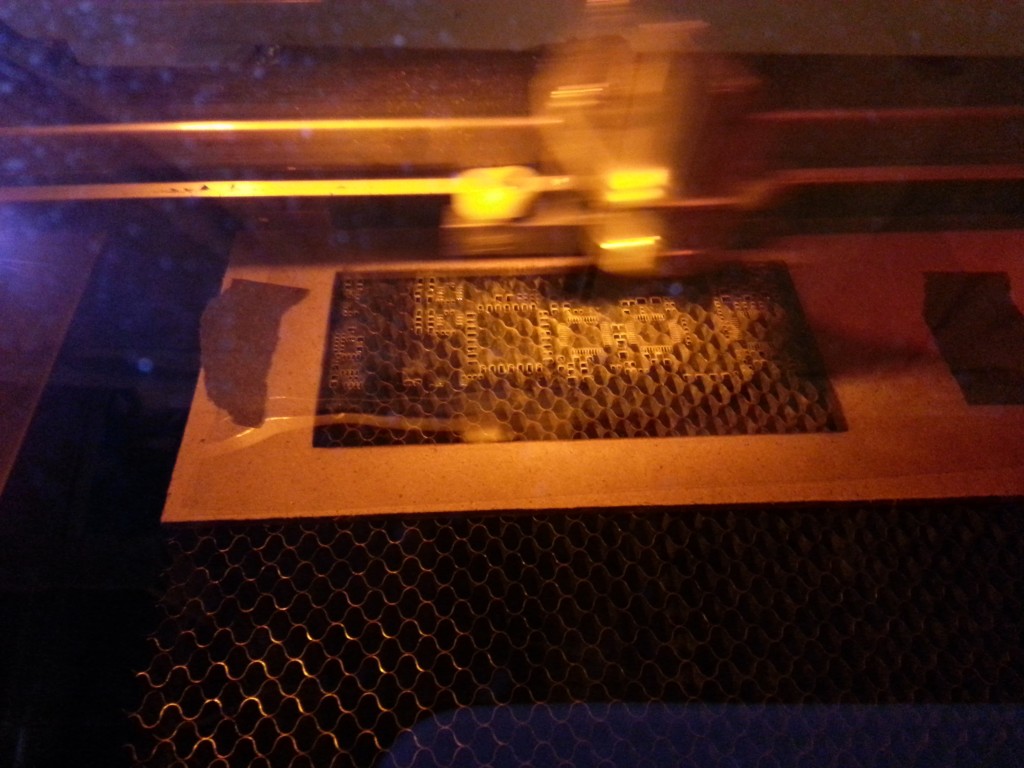

One of the big reasons to get the K40-III 40W engraving laser was to make stencils for PCBs. When I first got the machine, I ebay’d some 5mil laser transparencies as it sounded like some people had success with that. I really didn’t know what to expect, but I thought perhaps the best way would be to run with just enough power to burn through the plastic in order to minimize melting the edges. It worked ok, but was not very pretty. If I went slow enough to run the laser at minimum power, it would melt the edges. If I sped up, it wouldn’t cut entirely. So I put it on the backburner at that time. Soon thereafter I tore out the engraving table and put in some honeycomb material from LightObject on a fixed base and got to business with lots of wood cutting.

This week I finally had a chance to get back to figuring out the stencils. I ordered a roll of 3mil mylar from McMaster-Carr because I had an idea that thinner material might be better for the smaller surface mount stuff that I play with. Once it showed up, I got to work.

After fighting with MoshiDraw (software and controller that comes with many of these low cost lasers) and figuring out what the various engraving settings did, I starting running at different speeds to see what was best. I already knew that my initial settings were the wrong way to go… higher power and speed is better according to general consensus on the internet at large. So I started with my power at 15mA (works out to about 30W I think) and tried various speeds ranging from 16cm/s to 24cm/s. I also varied the amount I shrink the paste openings by, the laser step-over (called step for the x and distance for the y), as well as something called ‘addsize’ in Moshidraw. Haven’t figured out what that last one does yet… It defaults to 2 and I’ve settled on 0 just so it doesn’t muck things up.

Turns out that 18cm/s, a 5mil shrink on the pads, 15mA power, 0.1mm (or better yet 0.05mm if you have patience) step in x, distance 1 line, and having an open area under the mylar sheet works pretty damn well.

I’ll be soldering with it tomorrow and will report back the results.

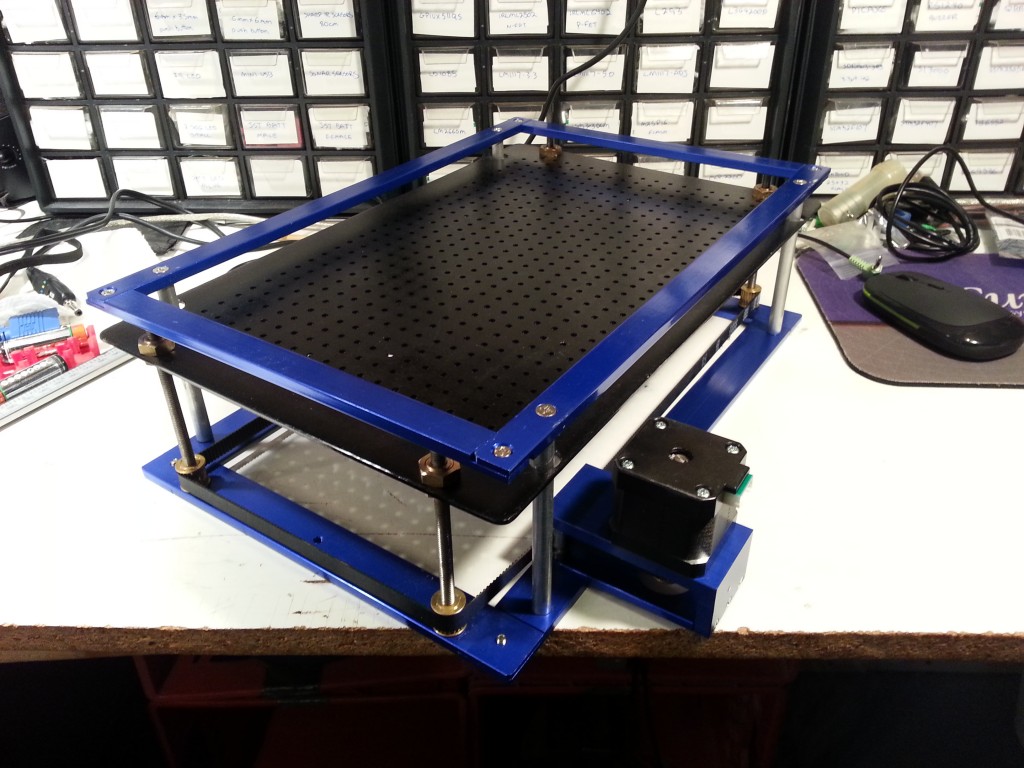

I got tired of a fixed z-height on the laser and kicked around a couple of ideas of how to build my own stepper controlled version. Before I got started, a power table at LightObject came in stock for pre-ordering at the start of February. The classic time-versus-money argument. I decided to spend the money. It arrived today and it is beautiful. Sadly I won’t be able to put it in this weekend (busy with the soldering mentioned above), so that’s a project for next weekend. A 70L/min aquarium pump also arrived so I’ll have to rig up an air assist for it also. The lens gets too smoky when cutting otherwise.

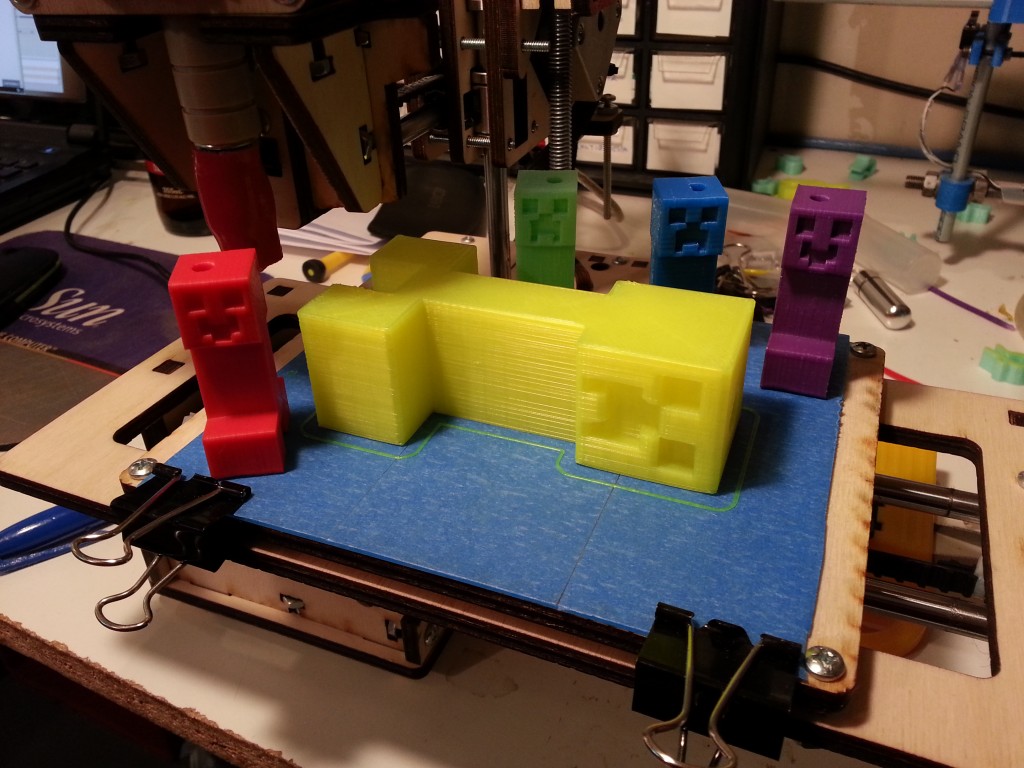

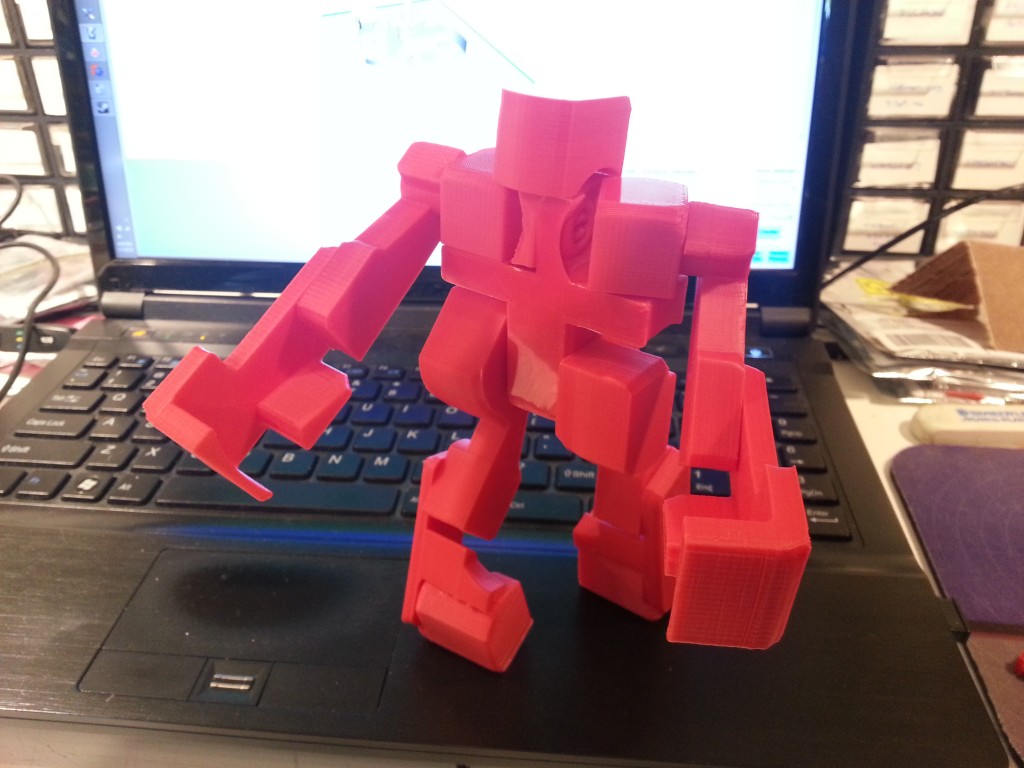

Speaking of next weekend, there is a 3D Print-a-thon happening at ArtEngine here in Ottawa on March 2nd, 2013 to celebrate the arrival of their Ultimakers (which are likely being bolted together as I write this). They put out the call for people with printers to come and show off, so I’ll have my Prusa and Printrbot Jr there.

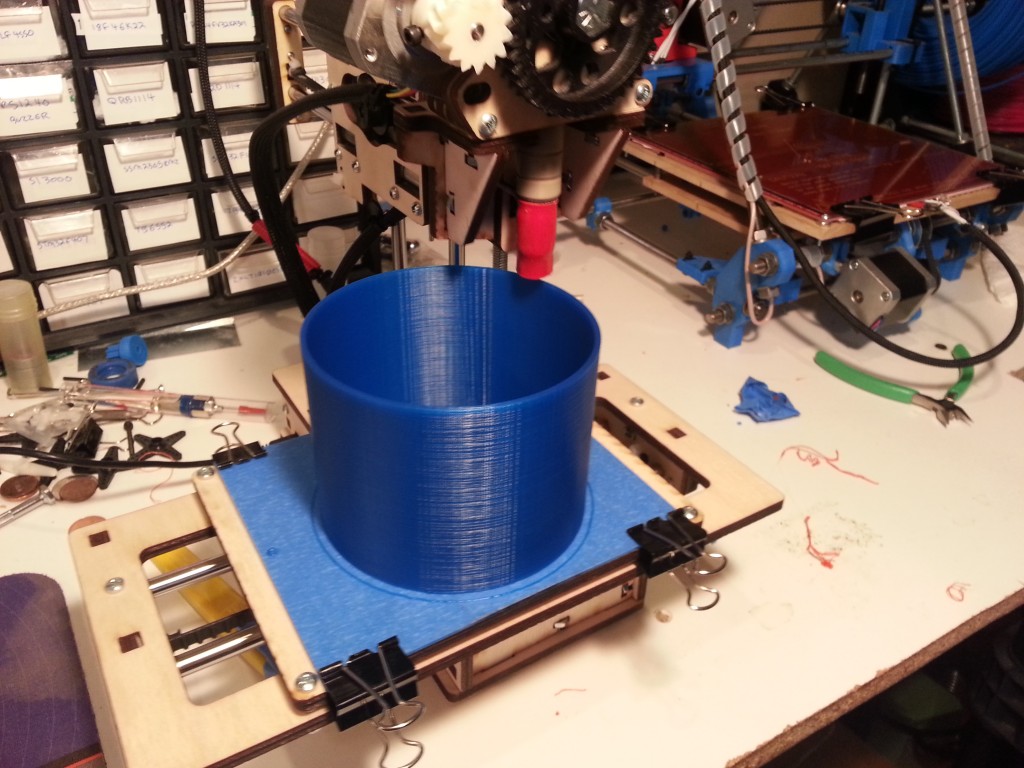

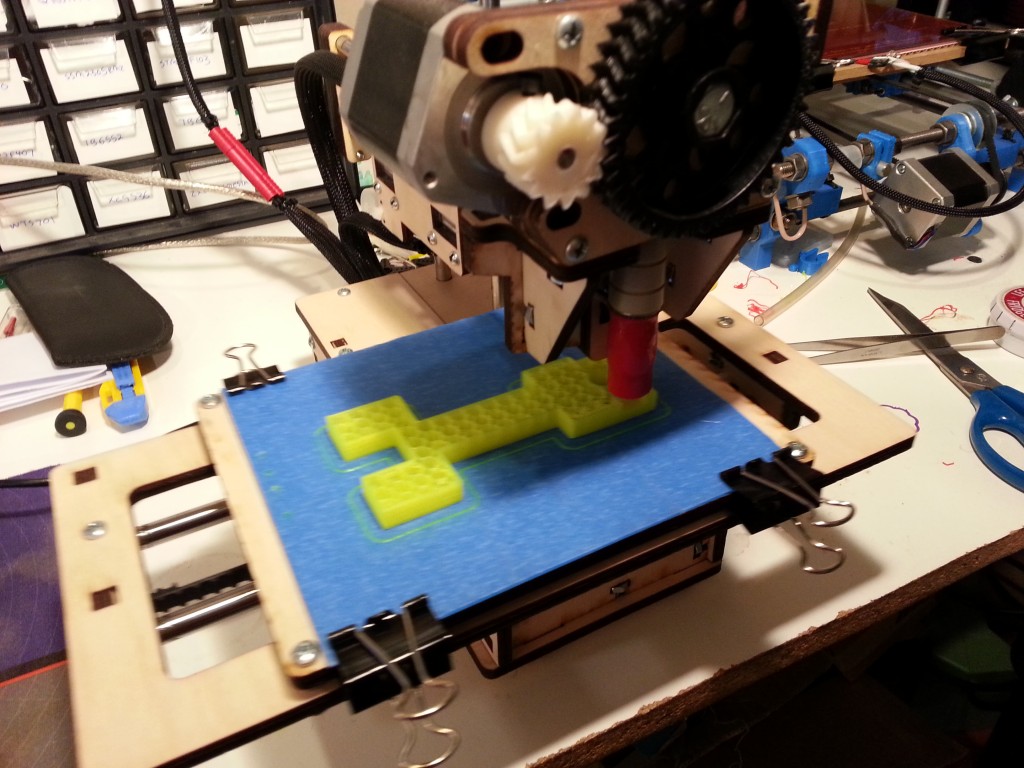

The Printrbot Jr. has been working like a champ. When I last posted I was struggling with getting the PLA to stick. After ordering some blank PCB material and some engraving bits for my CNC to make a hot-bed, I discovered that if I simply replace the blue 3M painters tape between each print, it works perfectly. No fuss, no muss. Dang… all that wasted time with sugar mixes, hotair guns, etc… I do rub the tape with a bit of acetone after putting on the tape… I have a crazy idea that it smooths out the wax on the tape and makes for a nicer finish. I could just be dreaming.

Anyhow, the Printrbot Jr. is working great. I think my longest print to date was two 3 hours prints, back to back, and the Jr. did it without breaking a sweat.

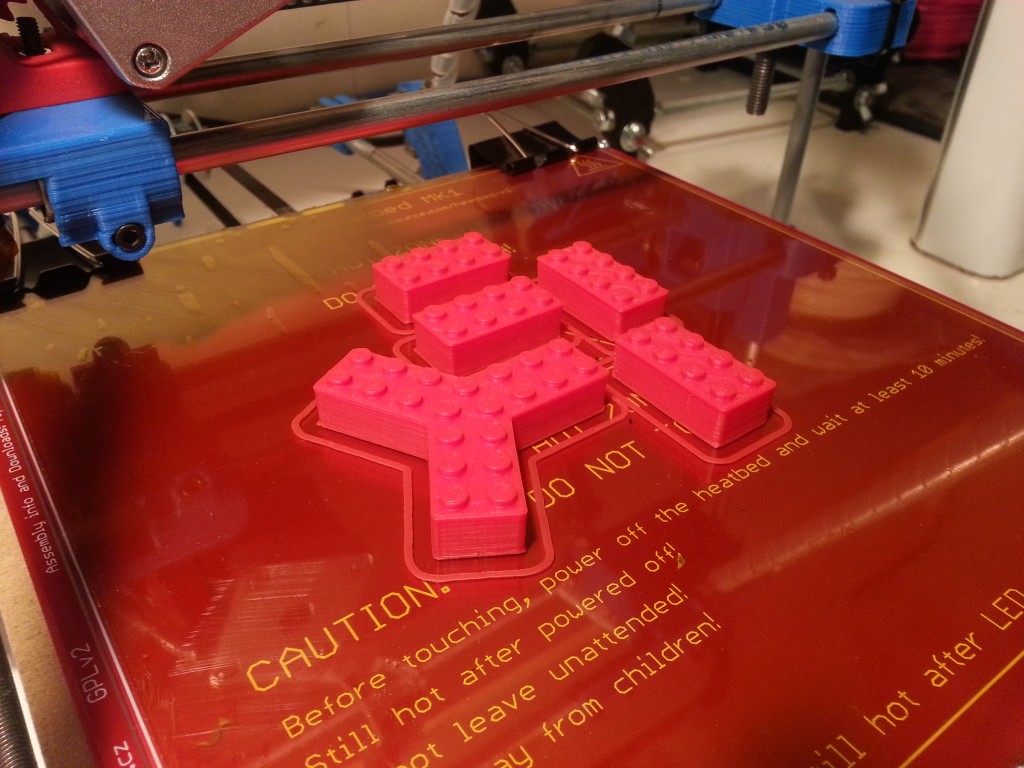

And the Prusa is back up and running thanks to Voxel Factory and their speedy delivery of a replacement J-Head. The J-Head puts my old Arcol V3 to shame I think. It has printed everything I’ve thrown at it. I highly recommend using the J-Head.